Imagine a world where products seem to float effortlessly through the air, navigating tight spaces and hazardous environments, all while increasing efficiency and reducing labor costs. Welcome to the fascinating world of overhead conveyor systems! These ingenious solutions have revolutionized industries such as food processing, pharmaceuticals, material handling, and industrial manufacturing. In this article, we will explore the advantages of overhead conveyor systems compared to other conveyor types and the industries they best serve.

Creating a Space Odyssey: The Art of Maximizing Usable Space with Overhead Conveyors

Overhead conveyors are the epitome of efficient space utilization. By making the most of vertical space, they free up valuable floor area for other essential operations, enabling businesses to optimize their production layouts and streamline their processes. This ingenious design helps companies enhance their facility’s overall productivity and increase output without having to invest in larger premises.

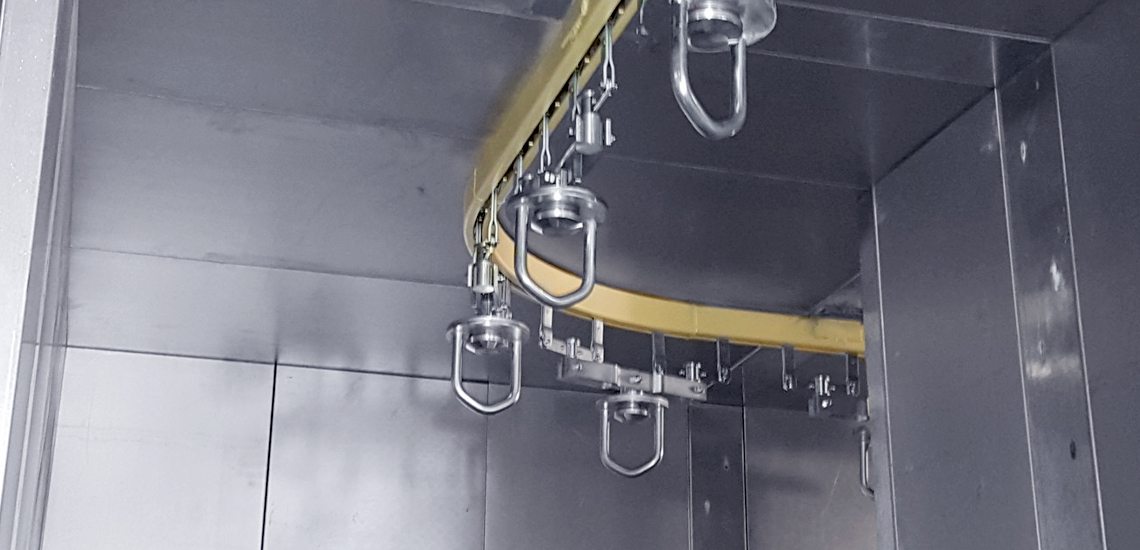

One of the most significant advantages of overhead conveyors is their ability to navigate tight spaces that traditional ground-based conveyor systems cannot. With overhead conveyors, products can be transported across multiple levels, taking advantage of the full height of a facility. This capability is particularly useful in industries with limited floor space or where the layout requires the conveyor to pass through areas with low clearance or around obstacles.

Moreover, overhead conveyors can effortlessly pass through areas that are inaccessible or hazardous to humans and robots, such as ovens, sprayers, or other hazardous environments. This feature allows for a continuous, uninterrupted flow of materials through the production process, reducing bottlenecks and minimizing downtime.

In addition to their space-saving benefits, overhead conveyors can be easily integrated with other equipment, such as automated sorting systems or robotic pick-and-place devices. This seamless integration further enhances the efficiency of the entire production line and reduces the need for manual handling of products.

Furthermore, overhead conveyors can be custom designed to accommodate the unique requirements of each facility, offering a tailored solution that maximizes usable space and meets specific operational needs. This flexibility allows businesses to adapt their conveyor systems to various product sizes, weights, and production volumes, ensuring that the conveyor system remains an effective and efficient solution even as their needs evolve.

A Safe Haven: How Overhead Conveyors Prioritize Safety in the Workplace

In today’s fast-paced industrial environments, safety is of paramount importance. Overhead conveyor systems are specifically designed with safety in mind, reducing risks and ensuring a secure working environment for employees. By eliminating clutter on the ground and keeping the products off the floor, overhead conveyors provide a safer and more organized workspace.

One of the most significant ways overhead conveyors prioritize safety is by providing employees with more space to work. With fewer moving parts on the ground, workers can move more freely and comfortably, reducing the likelihood of accidents and injuries. This additional space also enhances ergonomics, allowing employees to maintain proper posture and work more efficiently without straining their bodies.

Overhead conveyors minimize the need for human intervention in areas where there are dangerous risks, such as exposure to contaminants, extreme temperatures, or hazardous chemicals. By automating the transportation of products through these risky environments, overhead conveyors reduce employees’ exposure to potential hazards and help maintain a healthier work environment.

Additionally, overhead conveyors are designed with features that promote safe operation. For example, they often include guardrails, emergency stop buttons, and other safety devices that protect workers from potential harm. These safety features are crucial in preventing accidents and ensuring a secure workplace for everyone.

Moreover, overhead conveyor systems can be designed with enclosed tracks that protect both the products and the employees from dust, debris, and other airborne contaminants. This feature not only helps maintain product quality but also contributes to a cleaner and safer work environment.

The safety benefits of overhead conveyors extend beyond the immediate work area. By keeping the products off the floor and reducing the need for manual handling, these systems help prevent injuries related to lifting, carrying, and transporting heavy or awkward items. This reduction in manual labor not only contributes to a safer workplace but also helps companies minimize worker fatigue, boost morale, and reduce absenteeism due to work-related injuries.

Quality Meets Efficiency: The Perfect Harmony of Overhead Conveyor Systems

Overhead conveyor systems strike an ideal balance between maintaining product quality and enhancing efficiency throughout the production process. These systems are designed to optimize workflow, reduce waste, and minimize energy consumption, making them an excellent choice for businesses seeking to improve their bottom line while maintaining the highest quality standards.

One of the most significant benefits of overhead conveyor systems is their ability to adjust production rates according to demand. By incorporating advanced control systems and automation technology, these conveyors can be easily scaled up or down, ensuring optimal throughput and minimizing lead times. This adaptability is essential for industries that experience fluctuations in demand or need to accommodate seasonal changes in production.

Overhead conveyor systems are designed to minimize unnecessary manual transportation and rehandling of products, streamlining the entire production process. By eliminating the need for multiple material handling systems, businesses can reduce the risk of damage to products and minimize the chance of human error. This single, unified handling system ensures that products move smoothly and efficiently from one stage of production to the next, improving overall productivity and reducing the likelihood of costly delays.

Energy efficiency is another crucial advantage of overhead conveyor systems. These systems often consume less power than other conveyor types, thanks to their innovative design and use of advanced materials. For example, many overhead conveyors feature lightweight, low-friction components that reduce energy consumption and minimize wear on moving parts. This energy-efficient design not only lowers operating costs but also contributes to a smaller environmental footprint, making overhead conveyor systems an eco-friendly choice for businesses.

Furthermore, overhead conveyor systems can be customized to meet specific quality control requirements. For example, they can be integrated with automated inspection systems, ensuring that products meet exacting quality standards at every stage of the production process. This integration helps businesses maintain a consistent level of quality while increasing efficiency and reducing the risk of defects.

In addition to the quality and efficiency benefits mentioned above, overhead conveyor systems can also be tailored to accommodate various product sizes, weights, and shapes. This adaptability ensures that the conveyor system remains effective and efficient even as production requirements change or evolve, providing businesses with a long-lasting and future-proof solution.

Labor Cost Reduction Unleashed: The Power of Overhead Conveyors

In today’s competitive business landscape, controlling labor costs is a critical aspect of maintaining profitability and staying ahead of the competition. Overhead conveyor systems offer a powerful solution to this challenge, as they automate the movement of items throughout the production process, eliminating the need for manual transport and significantly reducing labor costs.

One of the key advantages of overhead conveyor systems is their ability to move products efficiently between various stages of production without the need for human intervention. By automating these tasks, businesses can save on labor costs by reducing the number of employees needed to handle product transportation, freeing them up to do work that can’t be automated or that requires human input, making the entire operation more productive.

Overhead conveyor systems also contribute to cost savings by reducing the likelihood of human error and product damage. With fewer workers involved in the handling and transportation of items, there is a lower risk of accidents or mishaps that can lead to costly delays, rework, or waste. This increased accuracy and reliability can result in significant cost savings for businesses over time.

Moreover, overhead conveyors can help businesses reduce their reliance on forklifts and other material handling equipment, which often come with high operating and maintenance costs. By minimizing the need for these costly resources, businesses can further reduce labor expenses and streamline their operations.

Industry Applications for Overhead Conveyors

The versatility of overhead conveyor systems makes them ideal for a wide range of applications and industries, including assembly lines, paint and coating processes, storage and retrieval systems, creative retail designs, and complex production setups. This adaptability allows businesses across various sectors to take advantage of the cost-saving benefits offered by overhead conveyors.

Industries that particularly benefit from overhead conveyor systems include automotive, leather, paper, food processing, garment, pharmaceutical, material handling, and industrial manufacturing. In these sectors, the ability to automate material handling processes and reduce labor costs is especially valuable, as it allows businesses to remain competitive and invest their resources in other value-added activities, such as research and development, marketing, or employee development.

Final Thoughts: Embracing the Overhead Conveyor Advantage

Overhead conveyor systems have revolutionized industries that value efficiency, safety, and cost reduction. By offering a unique combination of benefits, these systems are an ideal choice for businesses across various sectors, including automotive, leather, paper, food processing, garment, pharmaceutical, material handling, and industrial manufacturing.

Adopting an overhead conveyor system is not just an investment in technology, but also a strategic decision that can significantly impact your business’s success and sustainability. As industries continue to evolve and seek innovative solutions, overhead conveyors will play a crucial role in shaping the future of material handling and logistics.