Conveyor systems, especially overhead types, dramatically improve manufacturing efficiency by maximizing space, automating material movement, and supporting the transport of heavy-duty, bulky products, resulting in streamlined workflows and lower labor costs.

Core Efficiency Benefits

Automated conveyor systems maintain a continuous flow of materials between production stages, removing manual bottlenecks and human error. This allows manufacturers to increase throughput, consistently meet deadlines, and reallocate labor to higher-value tasks such as quality control and equipment maintenance. Integrated safety features, like emergency stops and sensors, further promote efficiency by ensuring a safer work environment.

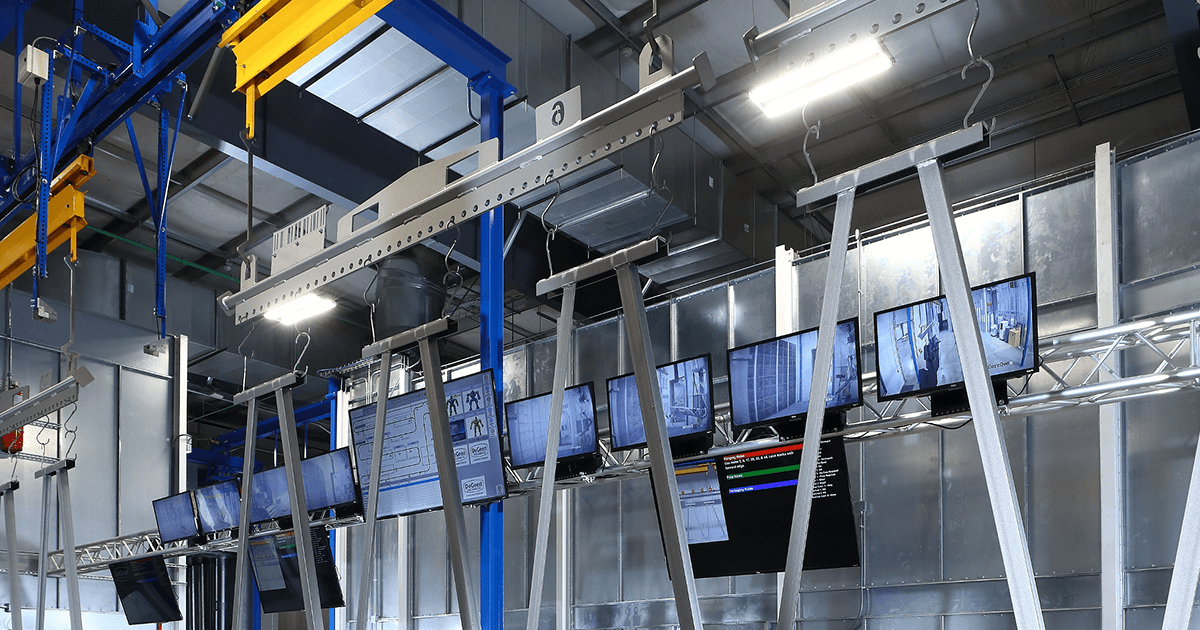

Why Are Overhead Conveyor Systems Essential?

Overhead conveyors enhance space utilization by transporting products above the production floor, freeing up valuable workspace for other operations or machinery. They also streamline product movement across long distances or multiple workstations, making them ideal for high-volume or heavy-duty manufacturing environments.

These systems excel at handling large, oddly shaped, or heavy components that traditional floor or belt conveyors can’t accommodate easily. By keeping production areas organized and obstruction-free, overhead conveyors help manufacturers achieve faster cycle times and higher process consistency.

How Do Overhead Conveyors Move Heavy, Large Products?

Richards-Wilcox Conveyor’s enclosed track and side-by-side overhead conveyor systems are engineered for flexibility, strength, and scalability. They efficiently transport bulky or high-capacity items through every stage of production, helping factories:

- Reduce manual handling and ergonomic strain

- Improve product flow and safety

- Minimize contamination risks

- Adapt quickly to layout or volume changes

Because these systems use modular, reconfigurable designs, they can easily integrate with robotics, sensors, or automated storage systems, supporting long-term growth and smart factory initiatives.

How Can I Optimize Large Product Movement?

- Overhead conveyors store and retrieve large or heavy items as needed, keeping them accessible but out of the way during downtime.

- Continuous transfer of oversized parts throughout the production line minimizes interruptions and reduces the risk of injury due to heavy lifting, enhancing worker safety and process reliability.

- Integration with robotics, sensors, and management software allows overhead systems to further automate inspection, sorting, and material routing, increasing overall facility productivity.

Frequently Asked Questions

What is an overhead conveyor system?

An overhead conveyor system is a material handling solution that moves products along a suspended track above the production area, freeing up floor space and improving workflow efficiency.

What types of products are best for overhead conveyors?

They’re ideal for large, heavy, or irregularly shaped items, like automotive frames, furniture components, or machinery parts, that can’t easily move on a floor conveyor.

How do conveyors reduce labor costs?

By automating transport between stations, conveyors cut the time workers spend lifting, walking, and staging materials, letting them focus on more skilled tasks.

Can conveyor systems integrate with smart technology?

Yes. Modern conveyor systems can connect with sensors, robotics, and data software for real-time tracking and predictive maintenance, which are essential for Industry 4.0 operations.

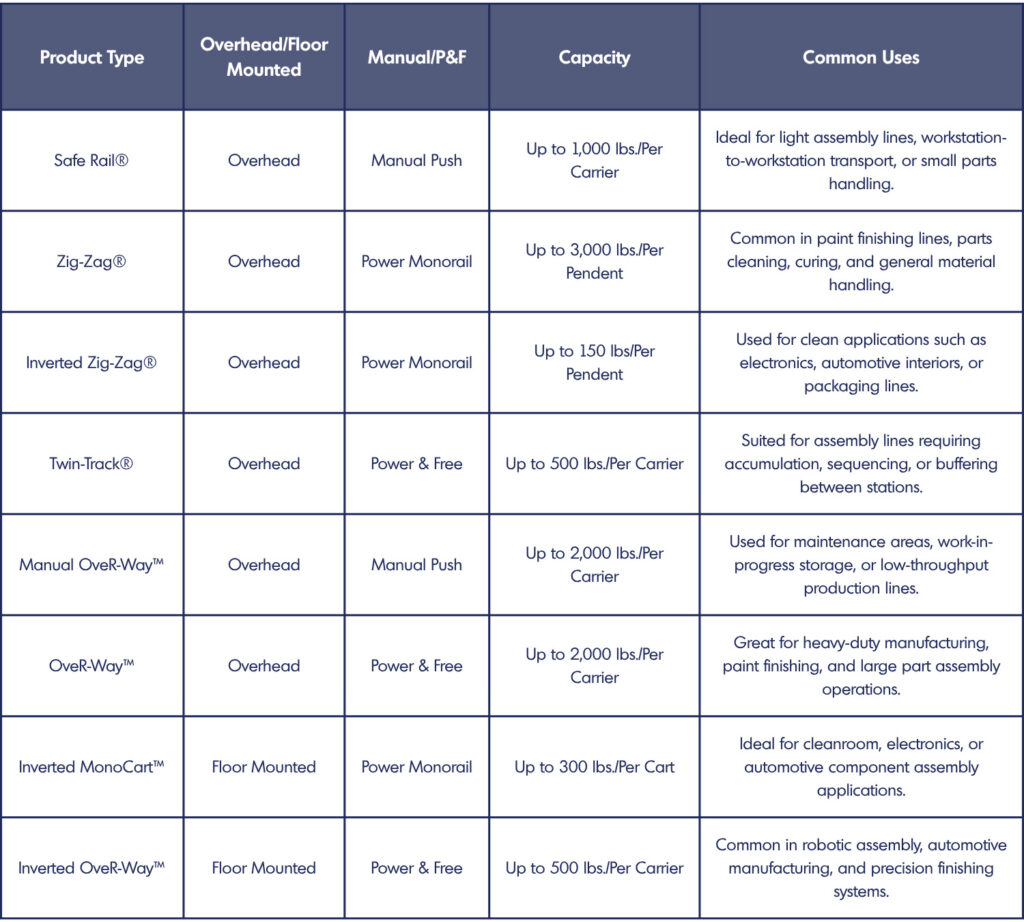

What Overhead Conveyor Systems Does RWC Offer?

Zig-Zag® Enclosed Track Conveyor

- Original enclosed track design we invented in 1938, known for its durability and versatility.

- Supports a wide range of manufacturing and distribution needs, including finishing lines, assembly, and storage/retrieval.

- Zig-Zag® Enclosed Track Conveyor’s compact track allows tight turns and space savings.

- Quiet, smooth operation with fewer system breakdowns.

- Scalable for simple or complex layouts.

Safe-Rail Monorail Enclosed Track Conveyor

- Hand-push overhead conveyor for transport and storage of products.

- Safe-Rail Monorail Enclosed Track Conveyor is an ideal starter system and can be upgraded to a powered solution anytime.

- Compatible with other RWC conveyor models for modular growth.

- Popular in automotive, finishing, and packaging applications.

Inverted Zig-Zag® Conveyor

- Clean operation for contamination-sensitive and finishing environments.

- Unique inverted pendant design enables forward and backward pivot for flexible movement, reducing wear on the chain.

- Inverted Zig-Zag® Conveyor is great for electronics, parts assembly, painting, and environments needing minimal debris.

OveR-Way™ Heavy Duty Over & Under Conveyor

- Heavy-duty power & free system, and can buffer, accumulate, and sequence loads.

- Dual load tracks handle individual loads up to 1,000 lbs. and tandem carriers up to 2,000 lbs.

- OveR-Way™ Heavy Duty Over & Under Conveyor is perfect for process flexibility: start/stop individual carriers as needed (paint lines, assembly, storage).

- <li aria-setsize=”-1″ data-leveltext=”” data-font=”Symbol” data-listid=”6″ data-list-defn-props=”{“335552541″:1,”335559683”