When it comes to automation, the most traditionally labor-intensive processes are the ones that stand to gain the most.

So why has painting been so slow to catch up? What recent advancements are changing that? And how can automated conveyor systems make your production line more productive and efficient than ever?

The Painting Paradox

In the world of industrial production, painting has long been a paradox.

On the one hand, it seems like a natural fit for automated conveyor systems, robotics and other Industry 4.0 technologies. Traditionally, painting is a labor-intensive process; in some facilities, employees must manually transport each product via forklift or wheel cart to a booth, then manually spray the product, drag it out of the booth to dry, and push it into a hot oven. All that manual labor makes the process slow and expensive—not to mention a potential safety liability, as employees must work in close contact with hot surfaces and machinery. Therefore, you would think these facilities would be eager to find solutions that would help them cut down on labor, right?

Historically, that hasn’t always been the case. In fact, many businesses that paint products on an industrial scale have been slow to adopt the very technologies that would help them cut labor costs and achieve better production volumes.

Why? In many cases, it’s because painting is a delicate, exacting process that requires fine motor control and adaptive decision-making—capabilities that were, until fairly recently, beyond most automated technologies. And the equipment that could achieve this level of precision and flexibility was out of the price range of most operations.

Fortunately for these businesses, the technology has caught up to their needs, costs have dropped significantly, and a growing number of painting operations are now embracing automation. In fact, this technology is becoming so widely used that many businesses must adopt it simply to stay competitive.

More Than a “Fresh Coat”

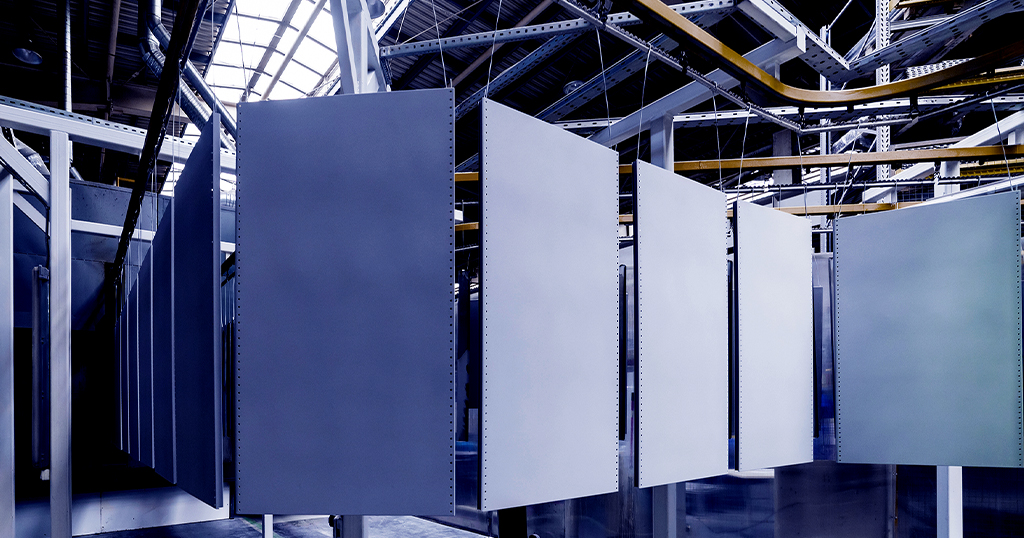

For painting applications, automated conveyor systems are more than just a “fresh coat” of tech. They transform nearly every step of the process.

Now, rather than a forklift or manual wheel cart, conveyor systems can transport products across a facility, freeing floorspace and reducing the need for labor. Meanwhile, robotic arms equipped with servomotors integrated into conveyor systems offer the precision and flexibility that was once only possible with human labor, and Richards-Wilcox’s innovative Conveyor Rotation system allows parts to be indexed on a rotating axis, helping facilities further automate their painting processes.

Businesses that paint products on an industrial scale have a lot to gain from automating their production line with conveyor systems. When implemented properly, these technologies can make your operation:

- More efficient, allowing you to cut labor costs, reduce waste, and increase your available floor space.

- More productive, increasing your production speed and volume, while reducing the probability of human error.

- Safer, reducing the need for employees to be in close contact with hot surfaces and potentially dangerous machinery.

Transforming Omega’s Painting Process

One of our clients is now seeing the benefits of these technologies in action.

Omega Tool Corp, a global company that paints plastic vehicle components in their Canadian production facility, recently partnered with Richards-Wilcox Conveyor to help automate their painting process. Using simulations and in-depth knowledge of their workflow, our team designed and installed a highly adaptive solution. Thanks to sensors and robotics integrated into their conveyor, the system not only transports and paints products automatically, but adapts to different sizes and shapes of components as they come down the line.

For Omega, the payoff of integrating this technology has been huge—they have less waste, greater flexibility, and better production volume than they could achieve manually.

Their facility is real-world proof that automation can revolutionize the industrial painting process. Businesses just need the right partner to bring it to life.

How Richards-Wilcox Can Help Transform Your Industrial Painting Process

When it comes to painting applications, most facilities are just scratching the surface of what automation, robotics and advancements in conveyor systems can help them achieve. At Richards-Wilcox Conveyor, we help you integrate these principles and technologies in a way that makes sense for your facility, your workflow and your output goals.

From designing conveyor solutions for new facilities to integrating Industry 4.0 technology into existing lines, Richards-Wilcox helps you create a smarter, faster, safer and more efficient operation—one that’s ready to compete today and evolve for the rapidly changing world of tomorrow.

Learn more about our legacy of innovation or get in touch with Richards-Wilcox to learn what we can do for you.