There are a few unchanging facts about your factory:

1) Your conveyor drives your currency. If you don’t have as much uptime as possible, you might as well be down.

2) At every stage of manufacturing, from production, loading, assembly, and unloading, to packing and inspection, you have to transport and handle materials. Whether you’re fabricating steel or running a fulfillment center, efficiency is the key.

3) A conveyor should be smooth, streamlined, and yield the maximum output for the minimum costs.

Material handling? We’ve got it handled.

Think of everything you can accomplish with automated controls. Reduced production errors. Repetitive decision-making for productive redundancy. Automatic stopping points. A seamless flow of material transport, from welding cell to assembly on line, to wash and finishing.

That’s exactly what you get with Richards-Wilcox Conveyor Power & Free systems.

If you have minimal floorspace and limited headroom, our Twin-Trak® Side-by-Side Conveyor is for you. It lets you call down work-in-process from overhead storage, as you need it. The cutting-edge controls allow for easy switching, with a 10-1,000lbs carrier capacity. Thanks to controlled accumulation, it eliminates the inefficient wait times of storage banks, ensuring a continual flow and boosting efficiency. It even keeps a travelling record of each work-in-process to detect and determine where defects occurred.

If your operators need a heavy-duty solution to adjust production rates and minimize lead times, look no further than OveR-Way™. Utilizing an over under configuration, OveR-Way is a high-capacity system for material transportation that can handle 2,000 pound loads. All this power, and its minimal footprint creates valuable usable space for add-on operations. The covered enclosed track prevents abrasive elements from deteriorating your chain, prolonging the life of your components and cutting down maintenance time.

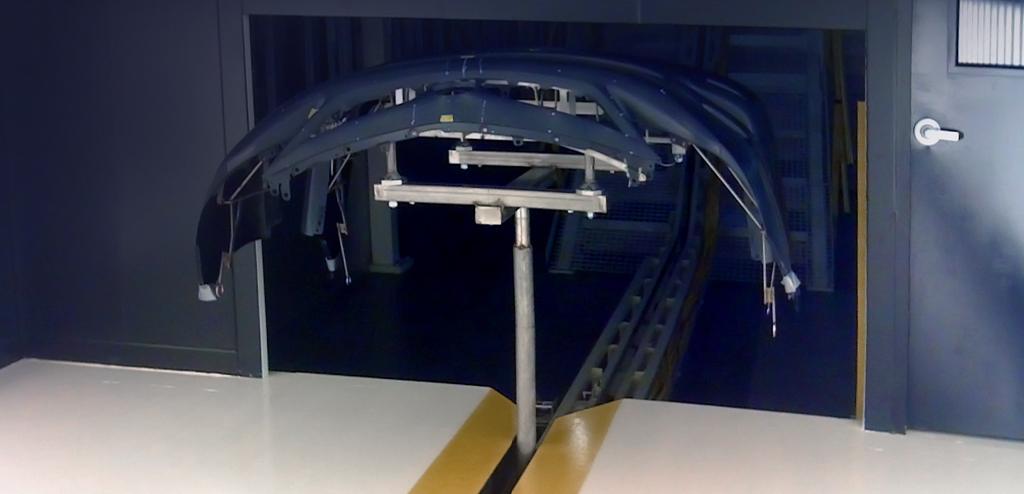

Need a floor-mounted system? Flip the script with OveR-Way Inverted, the ideal medium-capacity solution. When you need finishing capability, and you need it clean, this peerlessly ergonomic and energy-efficient system comes to the rescue. The inverted configuration means there are 360 degrees of accessibility to the top and sides of the product, making it the paintline platonic ideal. It’s also a robotic dream come true: robotic interfaces can be seamlessly integrated to ensure unmatched precision and safety.

No matter what system you choose, the benefits of evolving your plant with Richards-Wilcox Conveyor are boundless, and uniquely tailored to you. We design each conveyor system from scratch, ensuring it has the optimal footprint for your space. Whether floor-mounted or overhead, inverted or twin-track, you’ll see how it runs in real-time, before it’s even built: we put each design through its paces in a simulation to plan for all variables and maximize efficiencies.

There are so many ways to optimize your material handling processes – with Richards-Wilcox Conveyor, you’ve got the power (and free).