In the fast-paced world of distribution and retail, efficiency and reliability are paramount. Companies want to fulfill orders faster and improve their supply chain operations. As a result, they are looking for new ways to enhance their processes.

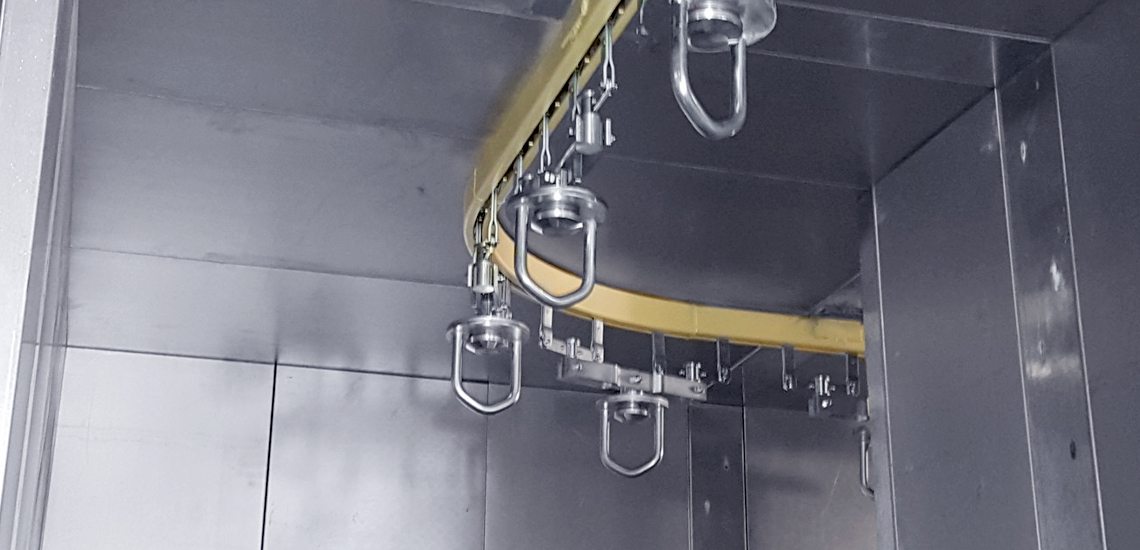

Zig-zag conveyors—especially Richards-Wilcox Conveyor’s Zig-Zag Enclosed Track Conveyor and Inverted Zig-Zag Conveyor systems—have become essential tools for modern distribution conveyor centers. These beneficial systems are designed to handle a variety of distribution tasks, from empty carton return to trash removal.

Let’s explore three key ways that zig-zag conveyors help distribution conveyor center processes.

1. Increased Productivity Through Streamlined Processes

One of the biggest benefits of zig-zag conveyors is that they make many distribution tasks easier. These tasks include handling totes, returning empty cartons, and removing trash. By using an enclosed track system that minimizes friction and prevents debris buildup, Richards-Wilcox Conveyor’s zig-zag conveyors allow materials to move smoothly through the system.

In most distribution conveyor centers, materials and items often go through several steps. They are sorted and packaged before reaching their final destination. Without an efficient conveyor system, this can lead to bottlenecks and delays that hinder productivity. Zig-zag conveyors help by moving goods continuously and reliably. This reduces waiting times and makes sure each item arrives on time.

Moreover, these conveyors are ideal for handling empty cartons, which are a common challenge in distribution centers. Empty cartons can quickly pile up, creating clutter and slowing down operations. By using a special empty carton conveyor system, facilities can manage this waste easily. This keeps it separate from other materials and helps avoid interruptions in productivity.

The seamless handling of empty cartons and other materials not only boosts productivity but also allows employees to focus on more critical tasks, ultimately improving overall operational efficiency.

2. Optimizing Space with Overhead Conveyor Applications

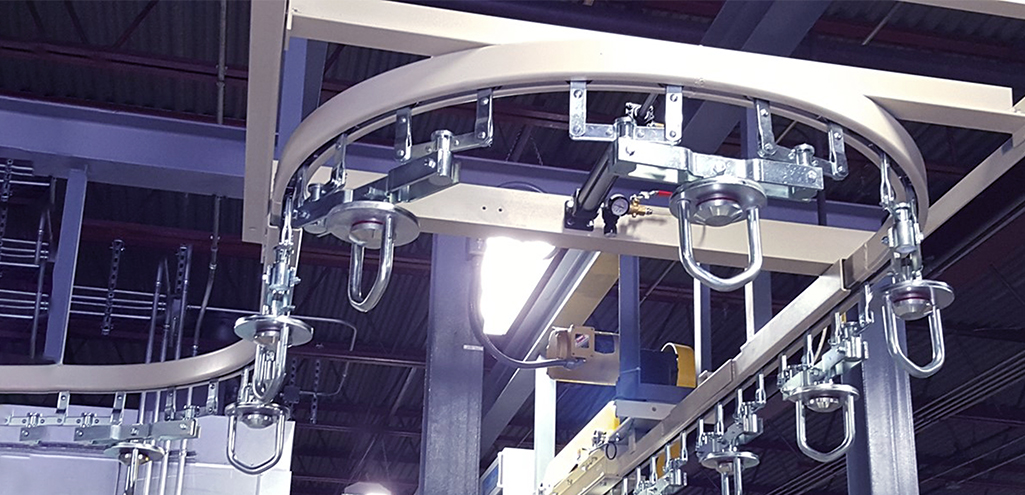

In distribution centers, space is a valuable asset. With limited floor space and more products to manage, it’s important to use every square foot wisely.

Overhead conveyors take advantage of unused vertical space, allowing facilities to clear up floor space for other activities. Zig-zag conveyors allow safer walkways for employees plus more floor space for other important equipment. This is especially beneficial in retail conveyor environments where space needs to be both flexible and safe to accommodate fluctuating inventory levels.

The zig-zag enclosed track conveyor system is also designed to navigate complex facility layouts, making it adaptable to various floor plans and building structures. This flexibility enables companies to install conveyors in unconventional spaces and along different elevations, further enhancing their space usage.

3. Lower Costs and Reduced Maintenance

Another major advantage of zig-zag conveyors is their ability to reduce operational costs and maintenance requirements. This maintenance can be costly and time-consuming, leading to additional downtime and lost productivity.

Zig-zag conveyors, particularly the inverted zig-zag model, are built for durability and minimal maintenance. The enclosed track design keeps dust, debris, and other contaminants away from important parts. This reduces the wear and tear that usually happens with open-track conveyors. By reducing contact with dust and debris, these conveyors need less cleaning and maintenance—saving time and money in the future.

Zig-zag conveyors cut down on manual work, which lowers labor costs and reduces the chance of human error. These conveyors’ operational efficiency can also help to reduce energy consumption, further contributing to cost savings over time.

Richards-Wilcox Conveyor’s zig-zag systems are designed to last, which translates to fewer interruptions, more consistent productivity, and lower replacement costs. Distribution centers that want to lower costs while keeping high performance should invest in strong conveyor systems as a smart choice for long-term growth.

Zig-Zag Conveyors: A Smart Investment for Distribution Conveyor Center Systems

Zig-zag conveyors offer numerous benefits for distribution and retail environments. By increasing productivity, optimizing space, and reducing costs, these systems have become essential assets for modern facilities looking to stay competitive in a demanding market. Whether handling empty carton conveyor systems or managing overhead conveyor applications, zig-zag conveyors provide the flexibility and reliability needed to streamline complex processes.

As retail and distribution industries grow, investing in solutions like zig-zag conveyors can help facilities meet customer demands. With their enclosed track design, minimal maintenance needs, and adaptability, Richards-Wilcox Conveyor’s zig-zag systems stand out as a reliable choice for forward-thinking distribution centers.