Today, servomotors are all around us. They open the automatic doors at your local grocery store, they lower the windows in your car at the press of a button, and they (hopefully!) make your next elevator ride feel nice and smooth.

While these examples are pretty simple, servomotors are also pivotal—literally—in the high-tech evolution of the factory environment. As facilities increasingly integrate robotics, automation, functional safety principles, preventative maintenance, and other Industry 4.0 concepts into their production lines, smart factories are using devices equipped with servomotors to be safer, faster and more efficient than ever.

In this blog, we’ll take a quick look at what makes servomotors unique, how they are being used in modern factories, and how Richards-Wilcox Conveyor can help you integrate smart technologies into your facility.

What are servomotors? What makes them unique?

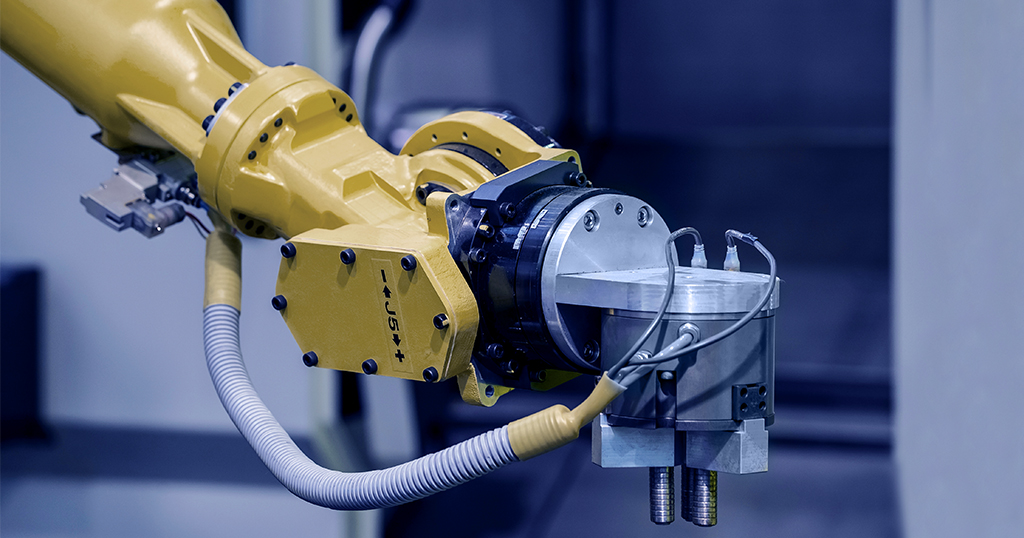

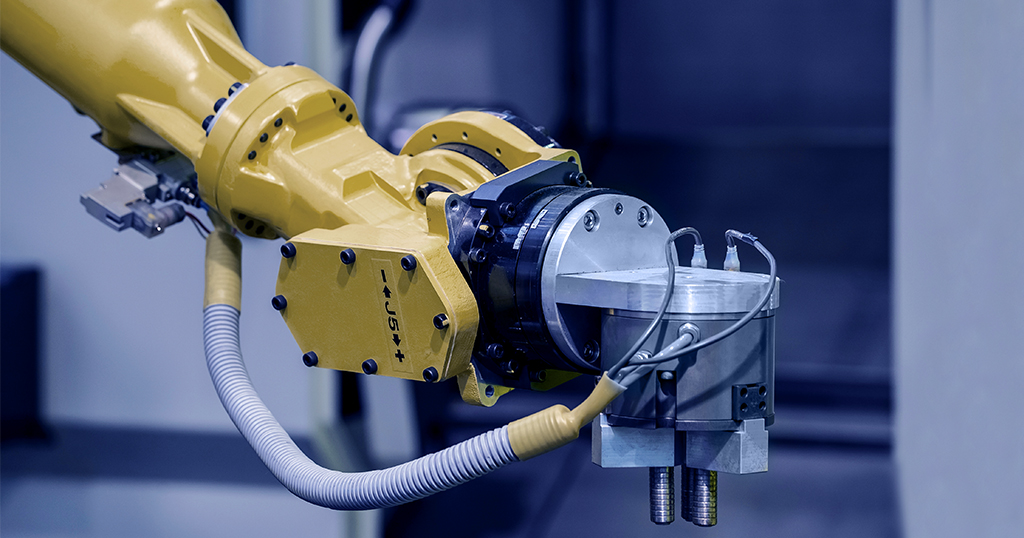

Servomotors enable robotic devices to independently perform applications that previously could only be done with human intervention.

Applying paint to car parts, distributing foods and medicine to containers, configuring the thousands of intricate components of an aerospace engine: all of these applications require a high level of precision, detail and flexibility. Until recently, most of them were beyond the capability of even the most advanced devices, requiring at least some human intervention. In recent years, however, the evolution of the servomotor, along with related computing and robotic innovations, has changed that, opening an exciting new chapter for robotics in the factory environment.

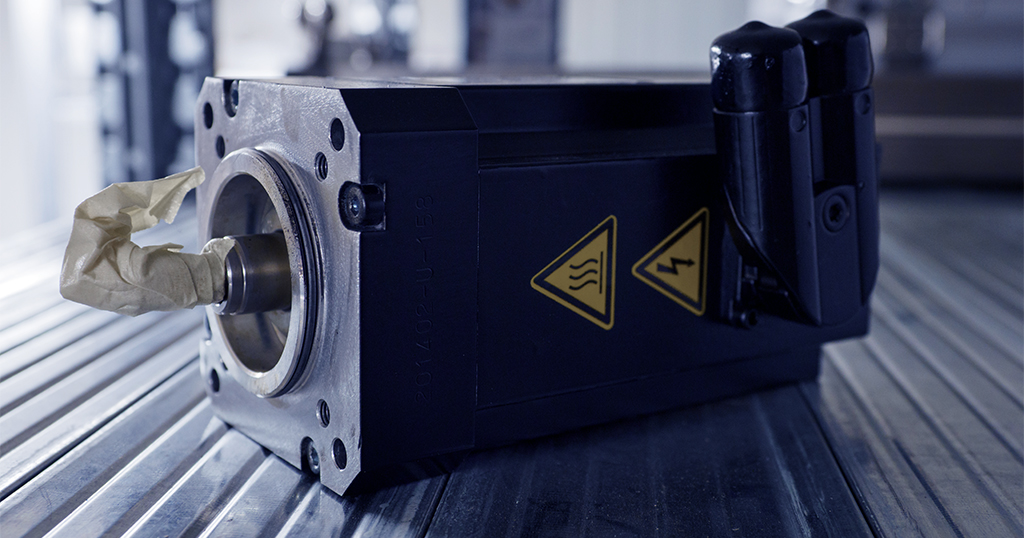

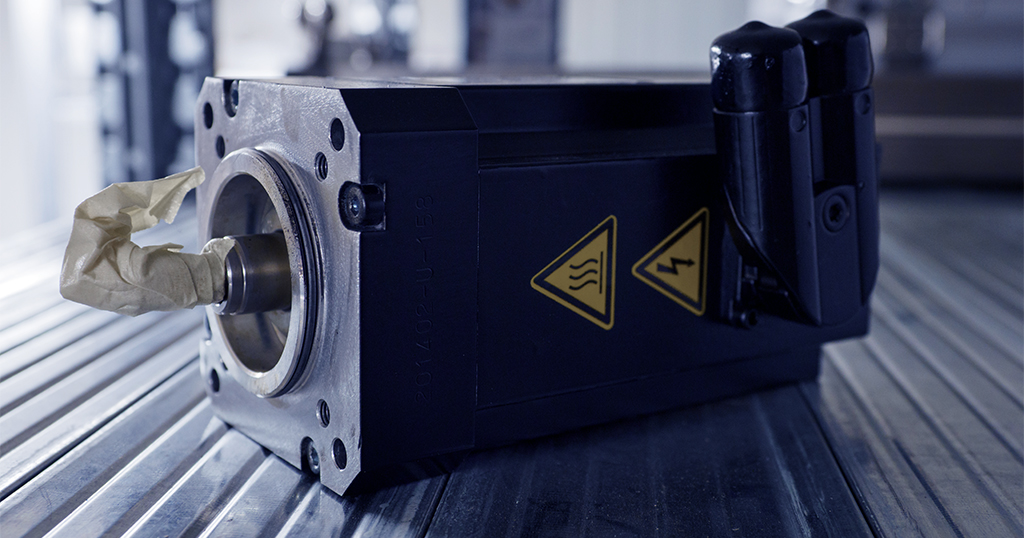

A servomotor is a rotary or linear actuator (a device that converts energy to motion) that can be moved to particular angles at particular velocities. Rather than a single part, a servomotor consists of a motor—a DC or AC, depending on the application—along with an output shaft and a controller equipped with sensors that allow for positional feedback.

The controller and its sensors are the key components. These parts allow the motor to ‘know’ precisely where it is positioned and to adjust automatically. That ‘spatial awareness’ is what makes this type of motor so uniquely capable. While other motors can produce power and determine their positions to a certain degree, servomotors bring a level of precision and adaptability that allows machines to not only match but outperform humans in the kind of applications that require fine-motor capabilities and ‘judgement calls.’

When combined with computers equipped with powerful algorithms, servomotors allow factories to create truly closed-loop systems, environments that automatically regulate themselves—no humans required.

Thanks to servomotors, applications that were once potentially dangerous, slow, tedious and expensive can be performed by robotic devices. That means a faster, safer, more efficient factory.

How are servomotors being used in today’s factory environments?

As we mentioned above, servomotors are a critical component in robotic devices and automated systems, allowing for greater precision and efficiency while reducing the need for human intervention. Due to the rise of the smart factory, these devices have become so ubiquitous that they are currently used in nearly every manufacturing sector, from food and beverage to aerospace and automobiles.

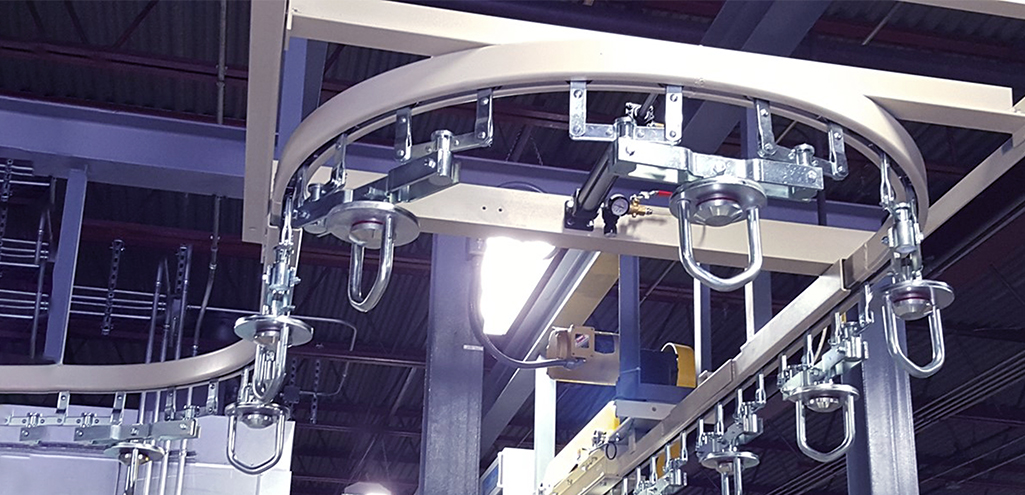

At Richards-Wilcox Conveyor, we design, create and install advanced conveyor systems in factory environments. A key part of our job is incorporating robotics, automation and other Industry 4.0 technologies and concepts into factory environments, while using simulations and engineering expertise to ensure that every element is optimized for maximum safety and efficiency.

While servomotors have long been an important component in our clients’ facilities, we have recently seen a sharp rise in their usage, especially when it comes to painting applications.

A good example is our client Omega, a Canadian company that produces vehicle components.

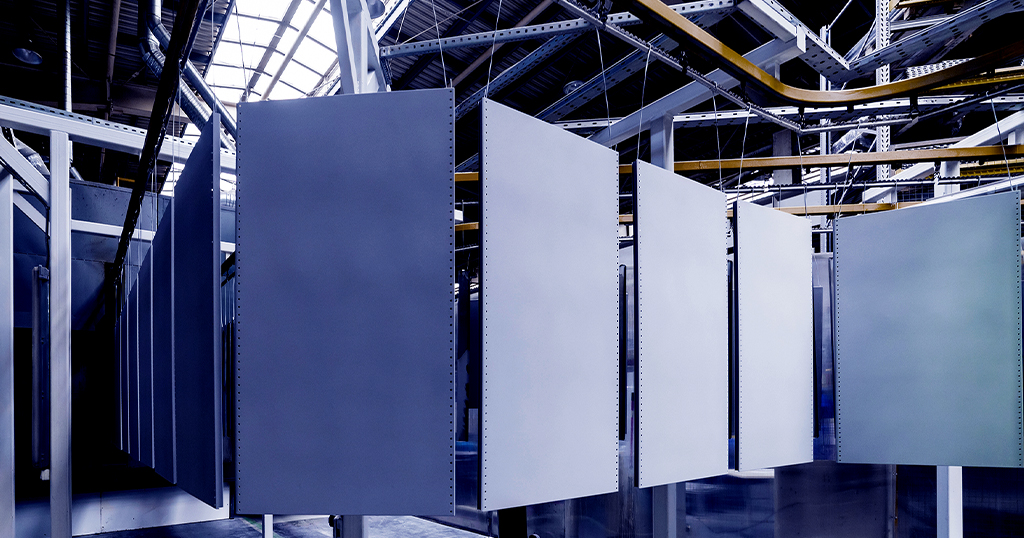

As part of their manufacturing operation, Omega paints thousands upon thousands of plastic truck parts. As these parts move down the conveyor line, a programmed robot sprays the parts with a liquid paint. Sounds simple enough, right? Not exactly—these components have fairly complex shapes, and they come in a variety of models and sizes. In order to get the correct aesthetic and avoid wasting paint, the application device must apply the paint at precisely the right angle and make adjustments based on varying sizes and shapes.

Our engineers worked with Omega and machine manufacturers to design a solution that automated the process, using robotic devices equipped with servomotors. The result was greater precision and speed, and a more efficient factory environment. Rather than having to make manual adjustments to the machine controls each time a new size or shape of truck part came down the line, the servomotor-equipped robots are able to quickly adjust to new conditions.

Today, Omega’s factory has less waste, greater flexibility, and better production times—all thanks to servomotors.

Richards-Wilcox can help you integrate edge technologies for a smarter factory.

Servomotors aren’t exactly new, nor are they considered an ‘edge’ technology in 2022. But they are pivotal in robotics, automation and other technologies and concepts that are transforming the modern factory.

At Richards-Wilcox Conveyor, we can help you understand how these technologies can impact your production line. Then, we create custom solutions and integrate them into your facility.

We use engineering expertise, along with digital simulations that help you see how specific design decisions could affect your overall environment, to help you determine the right machinery, technologies and layout for your factory.

While we specialize in the most fundamental component of the modern factory—the conveyor—we have a holistic understanding of the factory environment and our clients’ various industries. We leverage that knowledge to help you not only build a better factory for today, but evolve your business for the rapidly changing world of tomorrow.

Learn more about Richards-Wilcox Conveyor’s century of innovation—and discover how we can help you create a smarter factory today.