In the fast-paced world of the automotive and finishing industries, efficiency and precision are paramount. You’re constantly seeking ways to streamline operations while maintaining top-notch quality. That’s where the enclosed track conveyor comes into play.

Unlike traditional conveyor systems, these innovative tracks offer a streamlined approach to material handling, revolutionizing how items are moved in assembly lines. Their design encloses the moving parts, minimizes debris accumulation, and reduces maintenance needs.

These features make an enclosed track conveyor particularly suited for environments where cleanliness and reliability are paramount. Below, we delve into three key advantages of enclosed track conveyors and how they can transform operations in specialized fields.

What is an Enclosed Track Conveyor?

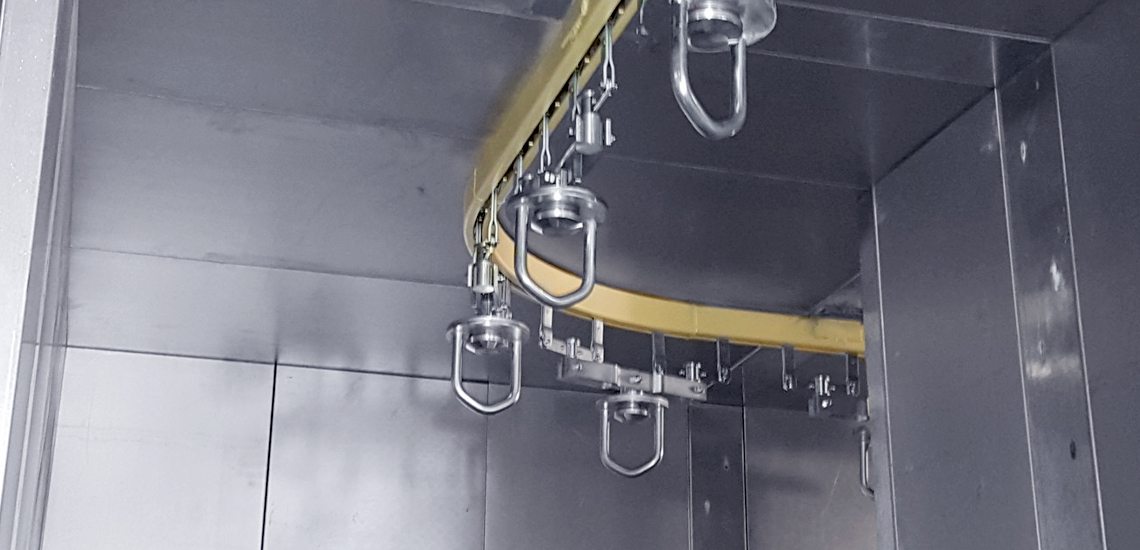

An enclosed track conveyor features a unique design where the conveyor chain and trolleys are housed within a fully enclosed track. This design sets it apart, offering distinct advantages in terms of cleanliness, safety, and versatility.

The mechanics of an enclosed track conveyor involve a continuous loop of chain that moves within the enclosed track, propelled by a series of sprockets and motors. The products or materials are attached to trolleys or carriers, which are connected to the moving chain. These trolleys glide smoothly inside the track, ensuring that the items being transported do not sway or jostle, which is particularly beneficial for sensitive operations like powder coating.

One popular variant of the enclosed track conveyor is the safe-rail monorail enclosed track conveyor. This type of system is often employed in environments where space is a premium, as it can be installed overhead, leaving the floor area clear. The monorail design simplifies conveyor system installation and engineering, making it a cost-effective solution for many industries.

The design and engineering of enclosed track conveyors allow for significant customization and flexibility. They can be configured to navigate turns, elevation changes, and even complex routing paths within a facility, making them ideal for facilities with space constraints or unique layout requirements.

The Benefits of an Enclosed Track Conveyor

Enclosed track conveyors offer a range of advantages that can significantly enhance the efficiency and safety of industrial operations. Let’s explore the key benefits that make these systems a preferred choice in industries such as automotive and finishing.

1. Easy assembly and adaptability

Enclosed track conveyors streamline your workflow with their easy assembly, ensuring minimal disruption to your operations. This efficiency is crucial in fast-paced environments where every moment of productivity counts.

Moreover, these conveyors are designed with future needs in mind. As your business grows and changes, so too can your conveyor layout. This compatibility with future layout changes means you won’t need to invest in an entirely new system when you reconfigure your space or expand your operations.

This adaptability is essential for industries like automotive manufacturing, where production lines often need reconfiguration to accommodate new models or process changes. With an enclosed track conveyor system, such modifications are not only possible but also far less cumbersome than with traditional conveyor systems.

Additionally, the longevity and sustainability of enclosed track conveyors make them a smart investment, thanks to their robust design and enclosed nature which protect the conveyor chain from environmental factors and wear.

This durability translates into a sustainable solution, reducing the need for frequent replacements or extensive maintenance. Longevity saves you money in the long run and aligns with sustainable business practices by minimizing waste.

2. Prevention of Contamination and Reduced Maintenance

Enclosed track conveyors are designed to keep both your products and the conveyor chain free from contamination. This is crucial for maintaining the quality of your output where even minor impurities can compromise the final product. With an enclosed system, you avoid the common pitfalls of dust, debris, and other contaminants, ensuring a cleaner, more reliable process.

This enclosed design also reduces the maintenance needs of the conveyor. Since the critical components are protected from the harsh industrial environment, wear and tear is minimized. This results in less time and money spent on upkeep, allowing you to focus more on production and less on maintenance.

A system that demands less maintenance naturally translates into more operational time. This means your production line keeps moving smoothly, enhancing overall efficiency and output. By choosing an enclosed track conveyor, you’re investing in a system that not only safeguards the quality of your products but also bolsters your productivity.

3. Enhanced Safety

Enclosed track conveyors significantly enhance safety in your workplace. One of the key features of these systems is the reduced risk of finger pinch points, a common concern with traditional conveyor systems. This design element makes a substantial difference in maintaining the well-being of your team.

With moving parts safely enclosed, the chances of accidental contact are minimal. This leads to fewer injuries and contributes to a safer, more comfortable working environment. Employees can focus on their tasks without the added worry of navigating around potentially hazardous equipment.

In addition to protecting your team, this safety feature aligns with industry standards and regulations, helping your operation meet compliance requirements. By investing in an enclosed track conveyor, you’re not just optimizing your production process; you’re also demonstrating a commitment to creating a safer workplace, which is invaluable for the morale and trust of your employees.

Start Leveraging the Benefits of an Enclosed Track Conveyor

Enclosed track conveyors offer substantial benefits, including efficient assembly and adaptability, contamination prevention, and enhanced workplace safety. These advantages make them an ideal choice for industries prioritizing efficiency, cleanliness, and safety. If you’re seeking the most evolved conveyor solutions, Richards-Wilcox Conveyor stands as the premier supplier.

With extensive experience in conveyor systems and engineering, we can custom design systems tailored to your specific needs, including the safe-rail monorail enclosed track conveyor and other innovative solutions. We also provide comprehensive support with conveyor systems installation. Contact us today to learn how our solutions can ensure your manufacturing and distribution operations are efficient and ready to adapt at a moment’s notice.