In today’s manufacturing industry, reducing carbon footprint is no longer just an ethical decision; it’s also a practical one. As global attention shifts towards sustainable practices, industries are pushed to make substantial changes in their operational techniques. For those operating within the realm of conveyor systems, the need for efficient, environmentally friendly strategies is paramount.

Here are some effective ways to minimize the environmental footprint of your conveyor system:

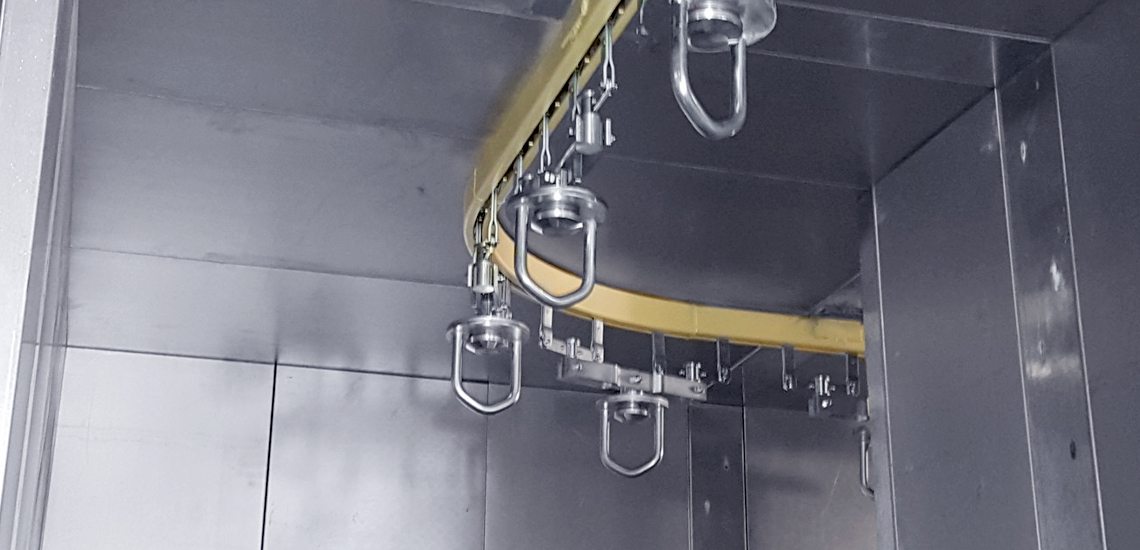

Invest in Long-Lasting Conveyor Systems

Making environmentally conscious decisions begins right from the first step – the selection process. By focusing on durability and long-term use, businesses can significantly reduce their environmental impact. The logic is simple: a system that lasts longer means fewer replacements and reduced waste from disposed machinery over time.

One of the most straightforward and effective strategies in this regard is to opt for conveyor systems that promise an extended operational lifetime. Such systems may initially seem more expensive, but their longevity often translates to cost savings in the long run.

At Richards-Wilcox Conveyor, our conveyor components are not merely manufactured; they undergo rigorous testing before they’re deemed fit for installation. This meticulous attention to quality ensures that each component offers longevity. Furthermore, the emphasis on adaptability means that as the manufacturing world evolves, our systems can too. It’s not just about building for now; it’s about building for the future, ensuring that clients remain in step with the rapidly changing manufacturing environment.

Increase Machinery Efficiency

Efficiency in machinery is multi-faceted. An efficient machine optimizes production, ensuring that tasks are completed swiftly and with minimal errors. But its benefits don’t stop there. An efficient machine is also one that reduces waste. This includes the raw materials used in the production process and the energy consumed during operations.

Thanks to advancements in technology, modern conveyor systems can be equipped with robotics, automation, and other solutions tailored specifically for any particular operation. Such integrations can elevate efficiency levels, ensuring that the machinery performs optimally at all times.

However, in the race to achieve peak efficiency, one aspect often gets sidelined: energy consumption. Conveyor systems, like any heavy machinery, can be energy-intensive. It’s crucial to choose conveyor motors designed with energy efficiency in mind. Such motors, while delivering the required performance, ensure that energy waste is minimized, resulting in reduced operational costs and lower carbon emissions.

Utilize Powder Coat Finishes

When it comes to finishing processes for machinery, traditional paint methods have long been the standard. However, they are not without their environmental concerns. These processes often result in considerable waste, and the solvents used can release harmful chemicals into the environment.

Enter powder coat finishes – a modern, more sustainable alternative. Instead of liquid paints, powder coat finishes use a dry powder which is cured under heat to form a protective layer. This method not only results in a sharper, more durable finish but also generates significantly less waste. Moreover, the absence of solvents means fewer volatile organic compounds (VOCs) released into the atmosphere. Businesses that adopt powder coat finishes not only enhance the durability of their machinery but also take a step towards a greener, more sustainable operation.

Incorporate Modular Conveyors

Embracing the modular design philosophy in conveyor systems opens the door to a world of sustainability and flexibility. Modular conveyors, by design, are comprised of segments or units that can be easily combined, altered, or replaced. This design philosophy promotes an environment of adaptability.

What makes modular conveyors a standout choice is their interchangeable nature. In a traditional conveyor system, when a part fails or becomes outdated, the whole system might need an overhaul, leading to increased downtime and waste. However, with modular conveyors, individual parts or segments can be swapped out, repaired, or upgraded without disturbing the entire system.

This means that instead of discarding large sections of a system due to minor faults, businesses can simply replace or mend the affected modules. Such a system doesn’t just lead to financial savings by reducing the need for whole-system replacements, but also plays a pivotal role in minimizing material waste, thus contributing to a more sustainable operation.

Prioritize Preventative Maintenance

Maintenance in the world of machinery isn’t just about fixing things when they break; it’s about ensuring they don’t break in the first place, or at least, not as frequently. This philosophy, known as preventative maintenance, is a proactive approach towards machinery care.

A conveyor system that is regularly inspected and maintained stands a far better chance of operating efficiently over an extended period. Regular checks allow operators to keep a close eye on the system’s health. By doing so, they can identify potential issues before they escalate into larger problems. For example, spotting a minor misalignment or wear in the early stages can prevent more significant damages and malfunctions down the line.

But the benefits of preventative maintenance extend beyond just smooth operations. By addressing issues early, you can extend the operational life of your conveyor system. This means fewer replacements in the long run, leading to both financial savings and a reduction in environmental waste. In essence, preventative maintenance is not just a cost-effective approach; it’s an eco-friendly one too. It emphasizes the idea of ‘prevention is better than cure’, ensuring that machinery remains in its prime for as long as possible, promoting efficiency and sustainability simultaneously.

Implement Energy-Efficient Power Solutions

The efficiency and sustainability of a conveyor system aren’t only determined by its mechanical components and maintenance routine; the power solutions driving these systems are equally pivotal. As global industries move towards greener operations, energy efficiency has become a cornerstone of modern machinery design.

Conveyor systems, being integral parts of manufacturing and distribution channels, consume a significant amount of energy, especially when operating around the clock. Therefore, selecting power solutions that prioritize energy efficiency can lead to multiple benefits:

- Cost Reduction: Energy-efficient power solutions tend to lower electricity bills. Over time, these savings can accumulate to significant amounts, proving that going green can also be financially rewarding.

- Reduction in Carbon Footprint: As conveyor systems consume less energy, they also produce fewer greenhouse gas emissions. This is a direct contribution to reducing a company’s carbon footprint, aligning operations with global sustainability goals.

- Longevity of Equipment: Energy-efficient motors and drives often come with the added benefit of advanced designs and superior materials, enhancing their durability. This means less wear and tear and extended equipment life.

- Adaptability: Modern energy-efficient power solutions are often designed with adaptability in mind. They can be adjusted to suit varying operational demands without compromising efficiency.

Final Thoughts

In the rapidly evolving landscape of industrial manufacturing, the focus on sustainability and efficiency has never been more prominent. As conveyor systems form the backbone of many operations, their optimization presents a golden opportunity for businesses to not only enhance productivity, but also significantly reduce their environmental impact. From investing in long-lasting components and energy-efficient power solutions to prioritizing preventative maintenance and embracing modular designs, each strategic decision plays a pivotal role. These integrative approaches ensure that industries can meet the dual demands of operational efficiency and environmental responsibility.

Going forward, businesses must recognize that sustainability is not just a trend, but a necessity. In an era where consumers and stakeholders are becoming increasingly conscious of environmental impacts, industries that proactively adopt eco-friendly measures stand to gain a competitive edge. By prioritizing sustainable practices in conveyor system management, businesses can foster a future where productivity and eco-consciousness go hand in hand, propelling the industry into a brighter, greener future.