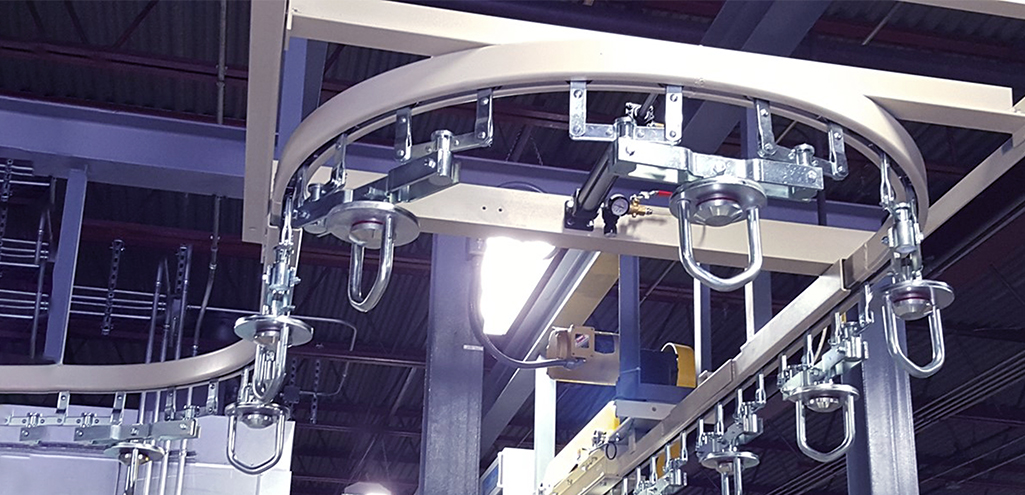

The success of your conveyor operation relies heavily on a conveyor system that is dependable and efficient. Richards-Wilcox Conveyor is the go-to source for innovative conveyor system designs, high performance conveyor chains, conveyor controls and software solutions that make your manufacturing environment more productive and your organization more profitable. In addition, we provide an extensive customer support system to ensure client satisfaction every time.

Education & Training

Offering full training and education on your control system is a significant part of our design and installation services. Our instructional programs are designed to provide our clients with an understanding of industrial material-handling equipment, robotic interfaces, automation, and any other elements of your conveyor that are essential for successful operation within your industry.

We provide information to all staff on how to run and maintain your conveyor control system effectively, creating a smoother transition for your factory. Successful implementation of high-performing conveyor systems is contingent on flawless design and installation; however, we understand that ongoing support plays an equally crucial role in achieving sustainable success. Our adept professionals ensure expeditious responses to all customer inquiries and grievances while delivering access to educational resources and training programs aimed at optimizing business performance.

Customers choose us as a trusted partner because we go above and beyond supplying high-quality conveying equipment. We understand the importance of educating our customers about how their systems work at every stage of development from design through installation & operation until maintenance & troubleshooting stages, enabling them to reduce costly downtime whilst boosting overall efficiency (resulting in higher profitability).

Simulation

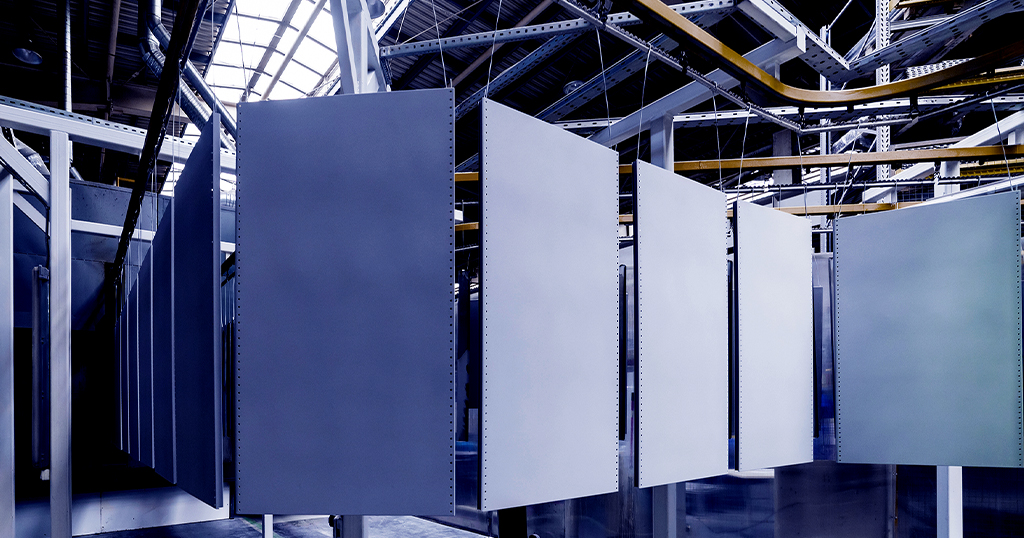

Installing or enhancing a conveyor system is a huge investment in your business operations. Therefore, the concern of unanticipated design changes or installation challenges that would require rebuilding part of your system can cause a lot of financial anxiety. With Richards-Wilcox Conveyor simulations, you can see your conveyor in action before it exists! Numerous scenarios can be tested, processes can be analyzed and optimized to identify bottlenecks, and waste can be reduced to improve efficiency before a conveyor system is ever installed.

Our simulation experts use their in-depth experience and cutting-edge technologies and methodologies to model different design and installation options, providing you with knowledgeable insights based on real-time data analysis that aid in better decision-making and conveyor system design. Our advanced simulation tools can also be utilized to examine how your conveyor components, including the conveyor control system, perform under different loading conditions without inhibiting precision.

Simulation is a great way to plan an extension of your current conveyor as well. Seeing how the new addition to your system can seamlessly integrate with your existing system prior to installation is a game changer for Industry 4.0 and helps our customers keep their conveyor projects on time and on budget.

Modernization

Businesses that are flexible and adaptable will have a strong advantage over their competitors as conveyor technologies continue to rapidly evolve. Reevaluating your operation on a regular basis to determine if improvements can be made through new technological breakthroughs is a way our support team can help keep your system ahead of your competitors and at its most effective. This process is called modernization.

When we collaborate with you on modernization, we will review the design of your current conveyor system, talk about your objectives, and create a strategy to achieve them. Our in-depth understanding of industrial material handling trends and technologies allow us to keep you ahead of the curve.

Maintenance & Parts Replacement

Richards-Wilcox Conveyor is not only a respected partner in new or expanding conveyor systems; we also provide top-notch solutions in conveyor system parts replacement and maintenance. To avoid having to worry about future costly repairs or unexpected shutdowns, our team can help you develop a maintenance schedule for your conveyor system. In addition, our specialists will evaluate your system and help you determine what replacement parts you may need, whether that’s a chain, belt, or anything in between. Finally, we provide thorough installation instructions and prompt delivery, to maintain (or enhance) your factory’s productivity and reduce downtime.

Ongoing Customer Support

Conveyor systems, like all technology, can have their hiccups. Therefore, we understand the significance of providing exceptional ongoing customer support. Our accomplished team has a vast knowledge of industrial material handling equipment, conveyor systems design, installation and more, which qualifies them as dependable sources of solutions for any potential problems for our clients. Our all-encompassing customer support ensures that every customer inquiry is handled effectively and efficiently. Client satisfaction is always our #1 goal.

Richards-Wilcox Conveyor Solutions

At Richards-Wilcox Conveyor, we boast a century of innovation, evolution, and craft, maintaining a finger on the pulse of conveyor system trends. We continue to lead our clients into the future by engineering the most effective conveyor solutions that have undergone intense conveyor simulation and testing.

We believe the conveyor system is the backbone of any operation, and it is our job to support your through the lifetime of your system. For more information on our systems and products, contact us.